CNC milling service and sheet metal fabrication are two indispensable processes in modern manufacturing. They offer unparalleled precision and efficiency, making them essential for a wide range of industries. In this blog post, we will explore the benefits of these services and how they can help businesses optimize their production processes.

CNC milling service is a computer-controlled machining process that utilizes rotary cutters to remove material from a workpiece. This highly precise method allows for the creation of complex shapes and designs with minimal error. By leveraging the power of machining online, businesses can tap into a vast network of CNC milling service providers, ensuring access to a diverse range of capabilities and expertise.

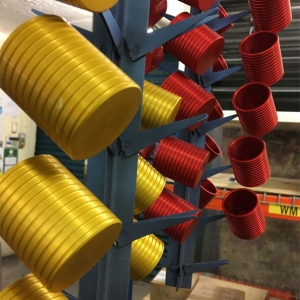

Sheet metal fabrication, on the other hand, involves the manipulation of thin metal sheets to create various products and components. It encompasses cutting, bending, and assembling processes to achieve the desired end result. With advancements in technology, such as the availability of aluminum die casting molds, sheet metal fabrication has become even more versatile and efficient.

One of the key advantages of CNC milling service and sheet metal fabrication is their ability to streamline production processes. By utilizing these services, businesses can reduce manual labor, minimize errors, and expedite production timelines. Furthermore, the availability of print prototypes enables manufacturers to test and validate designs before committing to full-scale production, saving both time and resources.

However, it's essential to consider the cost aspect when implementing these services. While metal CNC machine costs can vary depending on factors such as machine size and capabilities, the long-term benefits usually outweigh the initial investment. The precision, speed, and repeatability offered by CNC milling and sheet metal fabrication services often result in improved product quality and overall customer satisfaction.

In conclusion, CNC milling service and sheet metal fabrication are pivotal in maximizing manufacturing efficiency. By leveraging machining online, businesses can access a wide range of capabilities and expertise. The availability of aluminum die casting molds and print prototypes further enhances the precision and efficiency of these processes. Though metal CNC machine costs may vary, the long-term benefits often justify the investment. Embracing these services can help businesses stay competitive in today's fast-paced manufacturing landscape.