Macroscopic Displacement Reaction of Copper ii Sulfide in Lithium Solid-State Batteries

Copper ii sulfide (CuS) is an attractive electrode material for batteries, thanks to its intrinsic mixed conductivity, ductility and high theoretical specific capacity of 560 mAh g−1. Here, CuS is studied as cathode material in lithium solid-state batteries with an areal loading of 8.9 mg cm−2 that theoretically corresponds to 4.9 mAh cm−2.

The well-defined crystallinity of the copper particles has vanished. In accordance, also the Cu reflections in the XRD patterns disappeared. EDX mapping shows an overlap of Cu and S signals indicating that copper was re-oxidized during charging to form copper ii sulfide. We were not able to identify the type of copper ii sulfide (CuS, Cu2S, Cu2−xS, and so forth). The XRD results suggest that largely amorphous products are formed during charging. However, the high ICE value of around 95% indicates that the reaction is nearly reversed upon charging.

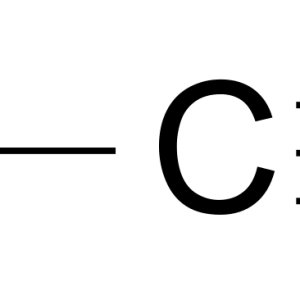

The conversion reaction of CuS with Li, however, behaves markedly different. Débart et al. showed (in cells with liquid electrolyte) that instead of forming a nanoscopic structure, lithiation of CuS leads to a macroscopic phase separation. During lithiation, Cu is extruded from the LixCu2S intermediate to form large crystals. This was attributed to the structural similarity between the LixCu2S intermediate phase and Li2S. Hence, the authors described the reaction as a displacement reaction.

Poor rechargeability, however, was identified as a major bottleneck. This issue can be solved by using an ether-based electrolyte as shown by Jache et al. For example, Cu2S shows a specific capacity of 200 mAh g−1 over 150 cycles using 1 m LiTFSI in DOL/DME as electrolyte and the voltage hysteresis is as small at 150 mV at 0.1 C. Interestingly, copper ii sulfides have also been used as additive for sulfur cathodes in SSBs to improve the rechargeability. A In-Li alloy counter electrode as used in most of these studies is not ideal and can complicate analysis of the voltage profiles.

An important advantage of copper ii sulfides is their high overall conductivity reaching 870 S cm−1 (CuS) and 70 S cm−1 (Cu2S), for example. These, for ionic compounds very high values are largely due to electronic conductivity. Studies on Cu2−xS with varying stoichiometry showed that the Cu/S ratio strongly influences the ionic (Cu+) conductivity while the impact on the electronic conductivity is quite small. An activation energy for ion hopping in Cu2−xS of 0.24 eV has been determined by Okamoto and Kawai from which a room temperature partial ionic conductivity of σ(Cu+) = 0.012 S cm−1 can be estimated. This is a very high value for ion conduction at room temperature (especially considering other ion conductors of interest for electrochemical devices). The high electronic conductivity may also eliminate the need for carbon conductive additives.

Copper ii sulfide (CuS) is an attractive electrode material for batteries, thanks to its intrinsic mixed conductivity, ductility and high theoretical specific capacity of 560 mAh g−1. Here, CuS is studied as cathode material in lithium solid-state batteries with an areal loading of 8.9 mg cm−2 that theoretically corresponds to 4.9 mAh cm−2.

The well-defined crystallinity of the copper particles has vanished. In accordance, also the Cu reflections in the XRD patterns disappeared. EDX mapping shows an overlap of Cu and S signals indicating that copper was re-oxidized during charging to form copper ii sulfide. We were not able to identify the type of copper ii sulfide (CuS, Cu2S, Cu2−xS, and so forth). The XRD results suggest that largely amorphous products are formed during charging. However, the high ICE value of around 95% indicates that the reaction is nearly reversed upon charging.

The conversion reaction of CuS with Li, however, behaves markedly different. Débart et al. showed (in cells with liquid electrolyte) that instead of forming a nanoscopic structure, lithiation of CuS leads to a macroscopic phase separation. During lithiation, Cu is extruded from the LixCu2S intermediate to form large crystals. This was attributed to the structural similarity between the LixCu2S intermediate phase and Li2S. Hence, the authors described the reaction as a displacement reaction.

Poor rechargeability, however, was identified as a major bottleneck. This issue can be solved by using an ether-based electrolyte as shown by Jache et al. For example, Cu2S shows a specific capacity of 200 mAh g−1 over 150 cycles using 1 m LiTFSI in DOL/DME as electrolyte and the voltage hysteresis is as small at 150 mV at 0.1 C. Interestingly, copper ii sulfides have also been used as additive for sulfur cathodes in SSBs to improve the rechargeability. A In-Li alloy counter electrode as used in most of these studies is not ideal and can complicate analysis of the voltage profiles.

An important advantage of copper ii sulfides is their high overall conductivity reaching 870 S cm−1 (CuS) and 70 S cm−1 (Cu2S), for example. These, for ionic compounds very high values are largely due to electronic conductivity. Studies on Cu2−xS with varying stoichiometry showed that the Cu/S ratio strongly influences the ionic (Cu+) conductivity while the impact on the electronic conductivity is quite small. An activation energy for ion hopping in Cu2−xS of 0.24 eV has been determined by Okamoto and Kawai from which a room temperature partial ionic conductivity of σ(Cu+) = 0.012 S cm−1 can be estimated. This is a very high value for ion conduction at room temperature (especially considering other ion conductors of interest for electrochemical devices). The high electronic conductivity may also eliminate the need for carbon conductive additives.