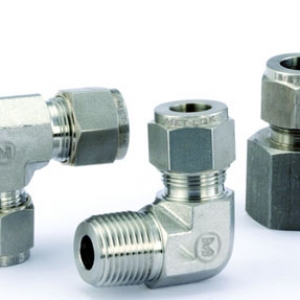

Ferrule Fittings Manufacturers in India

Nakoda Metal Industries is a prominent Ferrule Fittings Manufacturer in India. Our ferrule fittings are sold to a wide range of customers worldwide. In comparison to other market segments, we can give our esteemed clients these stainless steel ferrule fittings at a very inexpensive price.

Choosing the proper components is critical in the area of industrial applications, where precision, dependability, and safety are critical. The ferrule fitting is one such component that has grown in prominence in recent years. Ferrule fittings provide a number of characteristics that make them an ideal choice for a variety of industrial applications. In this blog, we will look at these benefits and why ferrule fittings are used in a variety of sectors.

What are ferrule fittings used for?

The circular clamp found on stainless steel ferrule fittings allows for the joining and connecting of wires, fibres, or posts. To avoid splitting, wear, or damage, the object is fitted with a certain form of ring or cap. The ferrule is an important component of a compression fitting assembly because it aids in sealing. It can be made of several materials, including stainless steel and graphite.

In the context of fluid systems and industrial pipelines, the importance of dependable and effective couplings cannot be stressed. Compression fittings, also known as ferrule fittings, have become essential components in a variety of industries due to their ability to provide safe connections, outstanding leak-tightness, and ease of installation. This article will go into detail about the use and benefits of ferrule fittings in a variety of industries.

Advantages of Ferrule Fittings

- Leak-Free Sealing:

The capacity of ferrule fittings to offer a leak-free seal is one of their key features. A secure connection between components is ensured by the double ferrule design, which includes a front and back ferrule. Ferrule fittings, when properly placed, form a tight, dependable seal that prevents leaks even in high-pressure and high-temperature settings. This leak resistance is crucial in industries like oil and gas, where any leakage can pose a safety risk and cause environmental harm.

- Ease of Installation:

When compared to other types of fittings, ferrule fittings are comparatively simple to install. The two-ferrule design makes construction easier, and they can be joined without the use of specialised tools or substantial experience. In industrial environments, the ease of installation lowers downtime and personnel costs, making ferrule fittings a viable solution for a variety of applications.

- Vibration Resistance

Industrial machinery is frequently used in hostile environments with vibrations and mechanical stress. Ferrule fittings are well-known for their high resistance to vibration-induced loosening. When subjected to vibrations, the ferrule's design produces a self-tightening effect, guaranteeing that the connection remains secure over time. This trait is especially helpful in industries such as automotive production and heavy machinery.

- High Pressure and Temperature Tolerance

Ferrule fittings are designed to endure high pressure and high temperatures. Ferrule fittings preserve their integrity even under harsh conditions, whether in hydraulic systems, chemical processing, or steam applications. This durability is critical for guaranteeing industrial process safety and efficiency.

- Minimal Maintenance

Ferrule fittings require little maintenance once they are properly installed. Because of their sturdy design and resilience to wear and tear, they can run efficiently for lengthy periods of time without the need for regular replacements or modifications. This feature adds to cost savings and downtime reduction in industrial processes.

For more details

Product: Ferrule Fittings Suppliers in India