What is M42 Steel?

It’s important to note that there might be slight variations in the naming conventions used in different countries。

Some names of M42 tool steels commonly used worldwide:

How to heat treating M42 Steel?

- Preheating:

The steel is preheated to a specific temperature range to ensure uniform heating throughout the material. - Austenitizing:

The preheated steel is heated to a high temperature, usually between 1160-1200°C(2120-2190°F), so that its microstructure is transformed into austenite, a high-temperature phase. - Quenching:

The austenitized steel is rapidly cooled by quenching in a suitable medium, such as oil or air, to achieve high hardness and martensitic structure. - Tempering:

Quenched steel will be tempered at a lower temperature, generally 540-565 ° C (1000-1050°F) or so, to eliminate internal stress, improve toughness and strength, hardness can reach 66HRC~69HRC.

What Kind of Thermal Treatment can M42 Steel Do?

1.Cryogenic Treatment:

The steel subjected to extremely low temperatures, typically below -100°C (-148°F), to further refine its microstructure and improve wear resistance.

2.Nitriding:

The steel is exposed to nitrogen gas or a nitrogen-rich environment at elevated temperatures, resulting in the formation of a hard nitride layer on the surface. This layer enhances wear resistance and reduces friction.

What are the Applications of M42 Steel?

1.Cutting Tools:

It is widely used for manufacturing high-performance cutting tools, such as drills, end mills, reamers, and taps. Its high hardness, wear resistance, and heat resistance make it suitable for machining tough materials like stainless steel, cast iron, and heat-resistant alloys.

2.Milling Cutters:

The steel is employed in the production of milling cutters used for precision milling operations. It enables high-speed cutting, excellent chip evacuation, and prolonged tool life.

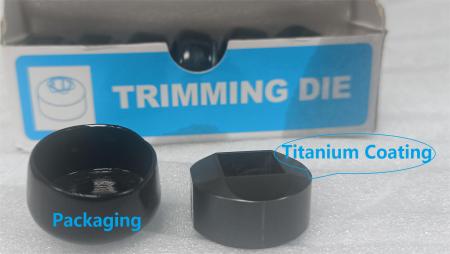

3.Punches and Dies:

It is utilized for creating punches and dies used in metal stamping operations. Its hardness and toughness allow for efficient and precise shaping of various materials.

4.Aerospace Components:

The steel is favored in the aerospace industry for manufacturing critical components, such as turbine blades, engine parts, and aircraft structural components. Its high strength and heat resistance enable reliable performance in demanding environments.

Conclusion

U-Need specializes in CNC machining services using premium materials like M42 steel. Contact us (E-mail: info@uneedpm.com) to discuss your project requirements and benefit from our expertise in precision machining。