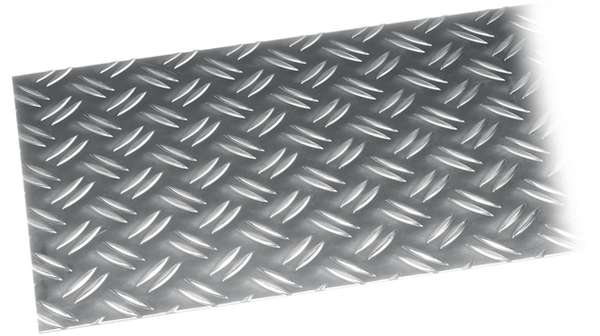

This Aluminium 6061 Chequered Plate is today found used in many industrial applications due to all excellent properties. The applications are railway, pesticides, automotive trim, power plants, pulp & paper industry, dairy & food processing, oil & gas industry. Because of their better alloys properties, Aluminium Alloy 6061 Chequered Plate provides a long life service. These plates are widely used in different industries and applications that require high heat and strength resistance alloys. These are the properties that are there with the presence of the carbon alloying elements. On the other hand, the plates are having other properties that are there with the other alloying elements which are there in the plates.

Plate Aluminium Alloy is the alloy in which aluminum is the major metal. The distinctive alloying elements are zinc, copper, magnesium, tin, silicon, and manganese. Two major categorizations are there like wrought alloys and casting alloys. Both of them are subdivided into the class that is non-heat treatable and heat-treatable. There are many different testing is performed on the products. These testing are performed to ensure the quality of our products to our clients. Testing like a tensile test, pitting resistance test, chemical test and many others are performed on the products.

| Standards | ASTM B209 / ASME SB209 |

|---|---|

| Material temper | O, T3, T4, T5, T6, T651, T6511 |

| Thickness (mm) | 0.2-400 |

| Width (mm) | 20-2650 |

| Length (mm) | Customized |

| Typical Products | Residential clapboard, Mobile house, Wine bottle cap, Beverage bottle cap, Cosmetic cap, Coating roll, etc. |

Chemical Composition

| Mn | Si | Cr | Cu | Fe | Zn | Al | Mg | Ti | Other Each/Total |

|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 0.4-0.8 | 0.15-0.35 | 0.15-0.4 | 0.7 | 0.25 | Remainder | 0.8-1.2 | 0.15 | 0.005/0.15 |

Mechanical Carbon

| Tensile Strengtd (PSI) | Yield Strengtd (PSI) | Shear Strengtd (PSI) | Elongation in 2″ | Brinell Hardness |

|---|---|---|---|---|

| 45,000 | 40,000 | 31,000 | 12 | 95 |