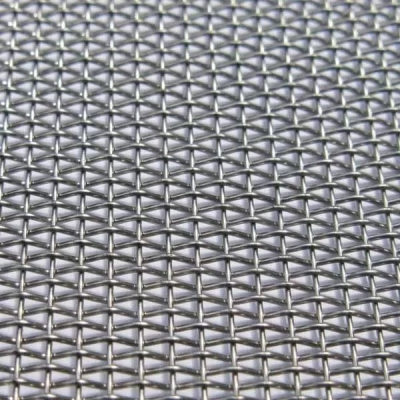

Stainless Steel 304 Wiremesh Sheets Exporters in India

Jaiman Metalloys LLP is one of the leading exporting houses for high-quality Stainless Steel 304 Wiremesh Sheets & Plates, which allows being matched for corrosion resistance with the austenitic and ferritic steel grades. Stainless Steel 304 Hexagonal Wire Mesh is always important to assess the suitability of a particular with full knowledge of the corrosive environment. Structures of SS 304 Welding Wire Mesh in swimming pools are known to ... moreStainless Steel 304 Wiremesh Sheets Exporters in India

Jaiman Metalloys LLP is one of the leading exporting houses for high-quality Stainless Steel 304 Wiremesh Sheets & Plates, which allows being matched for corrosion resistance with the austenitic and ferritic steel grades. Stainless Steel 304 Hexagonal Wire Mesh is always important to assess the suitability of a particular with full knowledge of the corrosive environment. Structures of SS 304 Welding Wire Mesh in swimming pools are known to be prone to SCC. The use of standard austenitic SS 304 Netting Wire Mesh is forbidden in several applications. The advantage of high-strength Stainless Steel 304 Woven Wire Mesh immediately becomes a disadvantage when considering formability and machinability.

The high strength of Spring Steel Wire Mesh also comes with lower ductility than austenitic grades. Due to their high chromium content, Fencing Wire Mesh offers excellent corrosion resistance in many media. SS 304 Wire Mesh has very limited use in hydrochloric acid because of the risk of uniform and localized corrosion. High–alloyed steels such as 304 SS Wire Mesh can be used in dilute hydrochloric acid. The resistance to pitting and crevice corrosion of Hexagonal Wire Mesh increases with the content of chromium, molybdenum and nitrogen in the steel. However, Welding Wire Mesh is convenient to use the Pitting Resistance Equivalent Number to rank the grades, where there is no single measure of corrosion resistance.

Does Stainless Steel Mesh Rust?

Most stainless steel mesh is rust resistant and will not corrode in normal atmospheric conditions. However, rust can form when exposed to certain environments or chemicals. For example, stainless steel mesh may rust if exposed to saltwater, acidic or alkaline solutions, or high temperatures.

When the stainless steel mesh is scratched or otherwise damaged, the protective layer is compromised, making it more prone to rust. As a result, it is critical to exercise caution when handling and installing stainless steel mesh to avoid damage.

SS 304 Wiremesh Specifications

Specifications : ASTM A 164 ASME SA 164

Standard : DIN, ASTM, BS and all International Standards

Length : 30m to 100″

Width : 1m to 48″

Type : Wire Mesh , Hexagonal Wiremesh, Welding Wiremesh, Netting Wiremesh, Woven Wiremesh , Spring Steel wire mesh, Fencing Wiremesh etc.

For More Details Visit Our Website- https://www.jaimanmetalloys.com/stainless-steel-304-wiremesh-sheets-plates-supplier-stockist-exporter/

Hastelloy C22 Pipes & Tubes Stockists in India

Hastelloy C22 Pipes are known for their high tensile strength and toughness. Hastelloy C22 Pipes are also known for their resistance to stress corrosion cracking, chloride ion corrosion, and stress cracking. In addition to this, they are known for their weldability. This alloy is also known for its high corrosion resistance and resistance to crevice corrosion. These pipes are also known for their flexibility and can be easily joined with other all... more Hastelloy C22 Pipes & Tubes Stockists in India

Hastelloy C22 Pipes are known for their high tensile strength and toughness. Hastelloy C22 Pipes are also known for their resistance to stress corrosion cracking, chloride ion corrosion, and stress cracking. In addition to this, they are known for their weldability. This alloy is also known for its high corrosion resistance and resistance to crevice corrosion. These pipes are also known for their flexibility and can be easily joined with other alloys.

Hastelloy C22 Tube is available in a wide range of sizes. They are available in sizes from 0.7 mm to 50.8 OD and in various gauges. In addition, these Hastelloy C22 Tubes are available in both single and double random lengths. Depending on the size, they can also be ordered in cut lengths.

Hastelloy C22 Tube is a very versatile alloy, making it an ideal material for manufacturing valves, pumps, and process control equipment.

Hastelloy C22 Pipes always demand them due to their proven excellent weldability. It is due to high corrosion resistance as the consumable filler wires and electrodes. The precise smooth bore Hastelloy C22 Pipes and tubes are the most suitable ones for bleaching operations, brackish water, closed-loop water systems, some food processing units, and specific other marine environments. The ones who opt for these incredible high-performance nickel alloys get to fight against the sour water gas and oil fields. The nickel-based alloys are cold-worked and offer numerous advantages such as toughness, low magnetic permeability, high strength, excellent corrosion resistance, and much more.

These pipes have always been proven for their valuable and versatile material, which could quickly solve various application and design problems. The alloy is also known for its excellent weldability and the flexibility to join easily with other alloys giving the users freedom of composition. This austenitic versatile nickel chromium molybdenum tungsten alloy has consistently been recognized for its excellent resistance to pitting, stress corrosion cracking, and crevice corrosion under various fluctuating environmental conditions.

For More Details Visit Our Website- https://www.jaimanmetalloys.com/hastelloy-c22-pipes-tubes-supplier-stockist-exporter/