In the world of manufacturing and construction, the performance of materials and components can make or break a project. When it comes to fasteners, their quality and durability play a critical role in ensuring the structural integrity and longevity of a building or machine. In this article, we will explore the significance of IS 2062 fasteners, especially those made from E250 grade steel, and how they can optimize performance across a wide range of applications.

Understanding IS 2062 and E250 Grade Steel

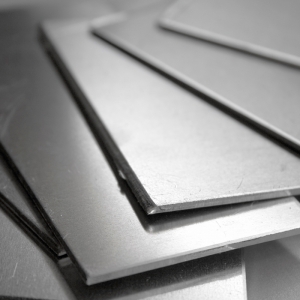

IS 2062 is an Indian standard that specifies the requirements for hot-rolled medium and high-tensile structural steel. It covers various grades of steel, and one such grade is E250. E250 is often used in the manufacturing of fasteners, among other applications, due to its excellent combination of strength, weldability, and ductility. It is ideal for components that require structural strength & the ability to withstand heavy loads.

Benefits of IS 2062 Fasteners Made from E250 Grade Steel

- Exceptional Strength: E250 grade steel is known for its high tensile strength. This property makes fasteners made from E250 steel capable of withstanding substantial loads and stresses. They are perfect for applications where safety and reliability are paramount.

- Weldability: IS 2062 E250 steel is easily weldable. This means that fasteners can be seamlessly integrated into a variety of structures, ensuring a secure and robust connection. Weldability also allows for efficient repairs and modifications if needed.

- Durability: Fasteners made from E250 grade steel are highly durable and corrosion-resistant. This extends the lifespan of the components they are used in, making them a cost-effective choice in the long run.

- Versatility: IS 2062 E250 fasteners find applications in a wide range of industries, including construction, automotive, and machinery. Their versatility stems from their ability to handle different environmental conditions and loads.

- Conformance to Standards: Using IS 2062 fasteners ensures that you are complying with industry and safety standards. This adds an extra layer of assurance to your project, whether you are building a structure or manufacturing equipment.

Optimizing Performance with IS 2062 Fasteners

- Proper Material Selection: The first step in optimizing performance with IS 2062 fasteners is selecting the right material. E250 grade steel is a versatile choice that can suit a wide array of applications. Ensure your fasteners meet the necessary standards for your specific project.

- Precise Installation: Fasteners should be installed with the utmost precision. Proper alignment and tension are crucial for their performance.

- Regular Maintenance: Like any other component, fasteners require regular inspection and maintenance. Periodic checks for wear, corrosion, or damage can help prevent structural issues down the line.

- Consult with Experts: If you are unsure about the right fasteners or installation methods for your project, consult with experts in the field. To meet your unique needs, they can offer advice and suggestions.

IS 2062 fasteners, especially those made from E250 grade steel, are essential components in various industries. Their exceptional strength, weldability, durability, and versatility make them a valuable choice for optimizing performance in construction and manufacturing projects. By selecting the right fasteners and following best practices for their installation and maintenance, you can ensure the long-term structural integrity of your projects while meeting industry standards and safety requirements.