Ananka Group is a leading Fasteners Suppliers in India. Many various industries, including engineering, construction, aerospace, automotive, and more, employ our fasteners. Our goods are renowned for their excellent quality, dependability, and durability. Our products are specifically made of stainless steel, an alloy renowned for its toughness and extended lifespan that resists corrosion.

The unsung heroes of the industrial and construction industries are fasteners. Despite their diminutive size, they are incredibly important in keeping everything in place. Fasteners occur in a vast range of sorts, each serving a particular purpose in everything from standard DIY projects to the building of enormous skyscrapers. We'll examine the most prevalent kind of fasteners and their uses in this detailed manual.

Types of Fasteners

Screws:

One of the most popular kinds of fasteners is the screw. We are experts in wood screws, thread cutting screws, and other screw types. They have a centre shaft that is encircled by a helical thread. Various screw varieties include:

- Wood Screws: They have a sharp tip for ease penetration and are ideal for use in wood.

- Machine Screws: Used in machinery or metal, they need a nut to keep them in place.

- Self-Tapping Screws: These are perfect for drilling their own holes in materials like metal or plastic because they feature a cutting edge.

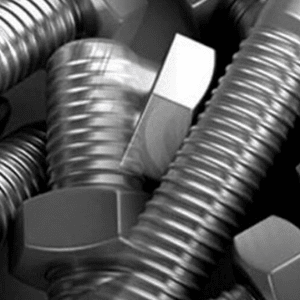

Bolts:

While screws and bolts share a tapered end, the latter does not. It's used to link or attach items together and is simple to assemble and disassemble. To join two or more items together, they need a nut. Bolt varieties include:

- Hex Bolts: The most typical kind of bolt, featuring a hexagonal head for a wrench.

- Carriage Bolts: Round head and square neck are used in woodworking applications to prevent rotation.

- Eye Bolts: features a circular loop at the end for securing to cables or ropes.

Nuts:

Bolts and nuts are used in conjunction to hold things in place. We accept orders and produce products in accordance with the needs of the clients. Typical nut varieties include:

- Hex Nuts:Equipped with hex bolt fittings to offer a solid connection.

- Lock Nuts: Possess a device that keeps them from losing as a result of vibration or torque.

- Wing Nuts: Hand-tightening is simple and frequently utilised for short-term purposes.

Washers:

Washers are thin, flat plates with a central hole. They disperse a fastener's weight, lowering pressure and shielding the material from harm. Washer types include:

- Flat Washers: Used to disperse the weight and give the nut or bolt a smooth surface.

- Spring Washers: Maintain tension to stop fasteners from loosening as a result of vibration.

- Lock Washers: Wedge-shaped profile was used in the design to stop nuts and bolts from coming undone.

Rivets:

Permanent fasteners called rivets are used to bind materials together. They come in a variety of shapes:

- Pop Rivets: They are frequently used for lightweight applications and are simple to set up.

- Solid Rivets: Ideal for heavy-duty applications that require a permanent, robust connection.

Finally, the fastener world is broad and diversified. The correct fastener for a project is determined by criteria such as the materials being joined, load-bearing requirements, and environmental conditions. Understanding the many types of fasteners and their unique applications is critical to the success and longevity of any construction or DIY project. The appropriate fastener is the key to a strong and solid connection, whether you're building a treehouse, assembling furniture, or erecting a skyscraper.

For more details:

Product Source: Fasteners Manufacturer in India