Petromet Flange Inc. Pipe fittings are crucial components in plumbing and industrial applications, connecting pipes and directing the flow of fluids. One key aspect that engineers and professionals need to consider is the weight of these fittings, often measured in kilograms (kg). In this article, we will delve into the factors influencing Pipe Fittings Weight Chart In Kg, exploring tradeoffs, challenges, and the significance of making informed decisions in this regard.

Factors Influencing Pipe Fittings Weight Chart In Kg:

Material Composition:

The choice of material for pipe fittings plays a pivotal role in determining their weight. Common materials include stainless steel, carbon steel, brass, and PVC. Each material has its own density, impacting the overall weight of the fittings. Engineers must carefully evaluate the properties of these materials and select the one that aligns with the specific requirements of the application.

Size and Dimensions:

The size and dimensions of pipe fittings are directly proportional to their weight. Larger fittings generally weigh more due to the increased material volume. Manufacturers provide detailed Pipe Fittings Weight Charts In Kg corresponding to various sizes, aiding engineers in precise calculations and selection based on project specifications.

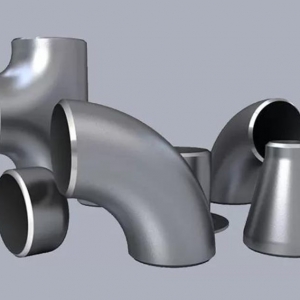

Type of Fittings:

Different types of fittings, such as elbows, tees, reducers, and couplings, have varying weights. For instance, a 90-degree elbow will have a different weight compared to a straight coupling of the same size. Engineers must carefully consider the types of fittings required for a particular system and analyze the weight distribution accordingly.

Tradeoffs and Challenges:

Strength vs. Weight:

Achieving the right balance between the strength of the fittings and their weight is a critical tradeoff. While heavier fittings may provide added robustness, they can also lead to increased installation and transportation costs. Engineers must carefully assess the application's demands and find the optimal balance between strength and weight.

Cost Considerations:

The weight of pipe fittings directly affects transportation costs and, consequently, the overall project budget. Choosing lighter materials can reduce shipping expenses but may compromise on durability. A careful cost-benefit analysis is necessary to strike the right balance between upfront costs and long-term performance.

Importance of Environmental Impact:

When evaluating Pipe Fittings Weight Chart In Kg, it's crucial to consider the environmental impact. Lighter materials often contribute to reduced carbon footprints during transportation, while heavier materials may have a higher environmental cost due to increased energy requirements in manufacturing. Engineers should factor in sustainability considerations to align with evolving industry standards and environmental consciousness.

Pipe Fittings Weight Chart In Kg

Petromet Flange Inc offers a precise Pipe Fitting Weight Chart in kg, mm, PDF. A thorough fittings Weight Chart for Pipe Fittings is provided below, highlighting length and diameter of Pipe Fitting for various sizes and wall thicknesses. This table is an excellent resource for finding the proper length, diameter, and size of Pipe Fitting to match the individual needs and applications of clients.

I can provide a general overview of common pipe fittings and their approximate weights. Keep in mind that actual weights may vary based on specific materials and manufacturing standards. Here is a basic reference chart for some commonly used pipe fittings weight charts.

These weights are approximate and may vary based on factors such as material type (e.g., carbon steel, stainless steel), manufacturing standards (ANSI, ASME, DIN), and specific design features. It's important to refer to the manufacturer's specifications and data sheets for precise information.

For more detail

Website: petrometfitting.com

Source: Pipe Fitting Weight

Other source: Flange Weight Chart in Kg.