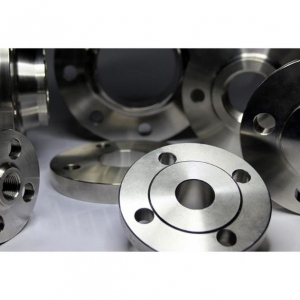

Nitech Stainless Inc is a high-quality Stainless Steel Flanges Manufacturer in India. These stainless steel flanges are ideal for instances where small high-pressure pipes are required. Stainless Steel Flanges were manufactured in accordance with regional and worldwide industry specifications using premium raw materials and cutting-edge technology.

Stainless steel flanges Manufacturer are required in a variety of industrial applications due to their durability, corrosion resistance, and versatility.By connecting pipelines, valves, and gadgets, these vital components ensure stability and smooth functioning.

These SS Flanges manufacturers in India improve their mechanical properties. Have been alloyed with additional materials.

Types Of Stainless Steel Flanges

Stainless Steel Slip On Flanges : We provide Stainless Steel Slip On Flange in a variety of sizes and shapes. When installing socket weld stainless steel slip on flanges, the pipe is placed into the socket end and a fillet weld around the top is made. Because the bore of the pipe and the flange are the same size, this assures proper gas and fluid flow throughout the piping system.

Weld Neck Flanges : Our Weld Neck Flanges division has an integrated forging plant that manufactures a wide range of flanges in line with various standards such as ASME/ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, UNI, and others.

Stainless Steel Blind Flanges : A blind flange, which is a solid disc, can be used to stop or block a pipeline. Stainless Steel Blind flanges are like conventional flanges, have mounting holes all the way around, and the gasket sealing rings are machined into the mating surface.

Threaded Flanges : A Threaded flange is a pipe-to-pipe connection that is not welded. SS To avoid leakage, SS Threaded flange is fastened onto the pipe with a tapered thread; however, a seal weld is used when necessary. When welding is not an option, such as in highly flammable or explosive conditions, the threaded flange is an excellent alternative.

Long Weld Neck Flanges : Long weld neck flanges (LWN) are longer than standard weld neck flanges and have an extended neck that functions as a boring extension. Our high-quality Stainless Steel Long Weld Neck Flanges , thoughtful client service, and in-house Stainless Steel Long Weld Neck Flanges processing skills have helped us establish ourselves as one of India's fastest growing and most reputable Stainless Steel Long Weld Neck Flanges suppliers.

What Are the Features of Using Flanges?

Secure Connection: Stainless Steel Flanges offer a secure and leak-proof connection between pipes and other equipment. This ensures that fluids and gases are delivered without leakage, reducing the danger of pollution and safety issues.

Easy Assembly and Disassembly: Flanges make pipeline system assembly and disassembly straightforward. This reduces downtime and associated costs by making maintenance, repairs, and component replacement easier.

Versatility: Using SS Flanges Manufacturer simplifies the assembly and disassembly of pipe systems. As a result, downtime and associated costs are reduced, while maintenance, repairs, and component replacements are simplified.

Pressure Containment: Flanges are intended to withstand certain pressure and temperature levels, ensuring that piping systems may transfer fluids and gases safely under different conditions.

Reduced Pipe Stress: SS Flanges allow for expansion and contraction in pipe systems due to temperature differences. This reduces the possibility of system damage and pipe tension.

Support for Special Components: Flanges are used to connect unique components to a pipe system, such as expansion joints, pressure relief valves, temperature sensors, and flow meters.

Flanges, in summary, present various advantages for industrial pipe systems in terms of security, dependability, maintenance, flexibility, and operational effectiveness. Many sectors rely on their ability to provide leak-free connections while also encouraging system flexibility.

For More Details:

Website: nitechstainless.com