Modern engineering challenges demand accurate analysis of fluid flow to ensure performance, safety, and efficiency. Computational solutions like CFD services have become indispensable tools for engineers seeking detailed insights into fluid dynamics without relying solely on physical testing.

Understanding CFD Services

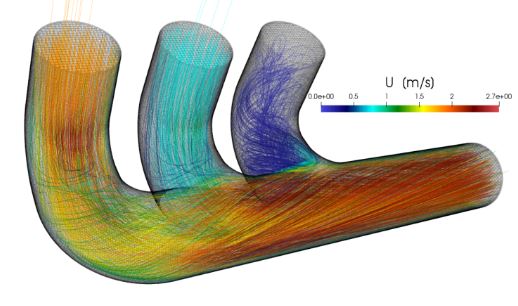

Computational Fluid Dynamics (CFD) uses mathematical models and algorithms to simulate the behavior of fluids in various systems. By providing a virtual testing environment, CFD services allow engineers to evaluate designs, predict performance, and make data-driven improvements.

These services handle:

- Compressible flows, such as gases at high velocities

- Incompressible flows, like liquids in pipelines

- Steady-state and transient analyses for dynamic systems

Key Benefits of CFD Services

Accurate Predictions

CFD services provide precise visualization of velocity, pressure, and temperature patterns, helping engineers identify design flaws early.

Cost and Time Efficiency

Virtual simulations reduce dependency on physical prototypes, cutting material costs and accelerating project timelines.

Safety and Reliability

By simulating extreme operating conditions, engineers can identify potential failures before implementation, ensuring safer designs.

Optimization and Performance

CFD allows testing multiple scenarios, helping refine systems for maximum efficiency and minimal energy loss.

How CFD Simulation Services Operate

A typical CFD workflow begins with creating a digital model of the system, including geometry and boundary conditions. The model is divided into small cells through mesh generation, enabling accurate computation of fluid behavior. The governing equations of motion, heat transfer, and turbulence are then solved to provide detailed insights into system performance.

Using CFD simulation services, industries can optimize designs efficiently. For example, in automotive engineering, airflow simulations improve aerodynamics and fuel efficiency. In energy applications, fluid simulations help enhance turbine performance and reduce energy loss.

Practical Applications

Aerospace

CFD services are vital in aircraft design for analyzing aerodynamics, wing structures, and propulsion systems, improving performance while minimizing material costs.

Automotive

Engine cooling, exhaust systems, and body aerodynamics can be optimized using CFD services, leading to better fuel economy and safer vehicles.

Power and Energy

From wind turbines to thermal plants, CFD simulations improve energy efficiency, reduce wear, and enhance system reliability.

HVAC and Construction

Airflow management in buildings ensures comfort and energy savings. CFD services enable accurate design of ventilation, heating, and cooling systems.

Choosing the Right CFD Services Provider

A reliable CFD provider offers expertise in handling complex simulations, provides actionable insights, and utilizes advanced software and computational resources. Look for providers with experience in multiple industries and the ability to handle both steady-state and transient analyses.

The Future of CFD Services

The integration of artificial intelligence and machine learning is transforming CFD services. AI-driven simulations reduce computation time, improve predictive accuracy, and enable real-time optimization, making engineering processes faster and more innovative.

Conclusion

CFD services are a powerful solution for engineers seeking precision, efficiency, and safety in fluid dynamics applications. By leveraging advanced CFD simulation services, industries can optimize designs, reduce costs, and achieve higher performance. CFD is no longer just a tool; it is a critical component of modern engineering success.